Swiss chronograph testing ensures precision and reliability in luxury watches. Key certifications include COSC, METAS, and the Geneva Seal, each with unique criteria. COSC focuses on movement accuracy, METAS tests fully assembled watches under various conditions, and the Geneva Seal emphasizes craftsmanship and origin. Here’s what you need to know:

- COSC: Tests uncased movements for accuracy (-4/+6 seconds per day). Covers 15 days, 5 positions, and 3 temperatures.

- METAS: Evaluates fully assembled watches for magnetic resistance (15,000 gauss), water resistance, and stricter accuracy (0/+5 seconds per day).

- Geneva Seal: Recognizes watches made in Geneva, focusing on aesthetics and precision (-1/+1 minute per week).

These certifications highlight the precision, durability, and artistry of Swiss watchmaking. Only a small percentage of watches meet these rigorous standards, making them highly sought after by collectors and enthusiasts.

What is COSC, METAS, Superlative Chronometer? Do they even matter?

COSC Certification: Contrôle Officiel Suisse des Chronomètres

When it comes to chronometer certification in the world of watchmaking, COSC stands as the gold standard. Known as the Official Swiss Chronometer Testing Institute, COSC sets the benchmark for precision and reliability in luxury timepieces.

COSC History and Purpose

COSC was established in 1973 to create a unified, impartial standard for testing Swiss watches, reinforcing Switzerland’s reputation for exceptional craftsmanship. The organization operates on three core principles: quality, rigor, and impartiality.

As COSC puts it, “It is thus a product with extremely high value added and therefore stands out quite clearly from standard quality watch production”. Over the years, this certification has become synonymous with excellence in horology.

The certification process applies to various timekeeping devices, including mechanical wristwatches, pocket watches, fixed-time devices, and quartz wristwatches, all tested according to ISO 3159 standards. For instance, Rolex began certifying its watches with COSC in 1951, and today, most Rolex timepieces leaving their Geneva facility proudly bear the chronometer designation.

COSC Testing Process and Requirements

The COSC certification process is among the most demanding in the industry. Each movement is put through 15 days and nights of testing, involving 65 handling events and 7 elimination criteria.

"The COSC certification must be earned. The COSC Certified Chronometer label is the result of unwavering precision, with every second measured. Certified with passion and no exceptions."

Movements are tested under five different positions and three temperature settings to ensure they perform consistently, regardless of how they’re worn or the environment they’re in. To meet COSC standards, a mechanical watch must maintain an average daily rate accuracy between −4 and +6 seconds per day. Here’s a quick breakdown of the COSC mechanical standards:

| COSC Mechanical Standards | Requirement |

|---|---|

| Average daily rate | −4/+6 seconds |

| Mean variation in rates | 2 seconds |

| Greatest variation in rates | 5 seconds |

| Difference between rates in horizontal and vertical positions | −6/+8 seconds |

| Largest variation in rates | 10 seconds |

| Thermal variation | ±0.60 seconds/°C |

| Rate resumption | ±5 seconds |

These strict criteria explain why COSC certification holds such prestige in the luxury watch industry. Although the testing doesn’t mimic everyday wear conditions, it ensures the movement meets exceptionally high standards.

COSC Certification Limits

While COSC certification is a testament to a movement’s precision, it focuses exclusively on the uncased movement, not the fully assembled watch. This means the tests evaluate the caliber’s performance without accounting for factors like the watch case, dial, or hands.

"The COSC makes it clear that the tests performed bear no relation to a simulation of watch behavior and performance when worn, but simply measures the timepiece’s excellence based on the severity of criteria."

COSC certification is also reserved for Swiss-made watches, further cementing the connection between Swiss craftsmanship and chronometer quality. Its exclusivity is evident in the numbers: only about 3% of Swiss watches are COSC certified annually, with 5% of Swiss-made mechanical watches and just 0.2% of Swiss-made quartz watches earning this distinction. Each certified movement is assigned a unique number and certificate, ensuring both traceability and authenticity.

For watch enthusiasts and collectors, COSC certification is more than just a mark of precision – it’s a symbol of reliability and durability. With proper maintenance, a COSC-certified movement promises accurate timekeeping for a lifetime, making it a sought-after feature and a worthwhile investment.

METAS Certification: Master Chronometer Standards

While COSC certification has long been the gold standard for Swiss watches, METAS certification takes things a step further. Overseen by the Swiss Federal Institute of Metrology, METAS has introduced the Master Chronometer certification, which puts watches through a more rigorous and comprehensive evaluation. This process blends traditional precision testing with modern challenges, ensuring watches meet the highest standards of performance.

How METAS Differs from COSC

The main distinction between METAS and COSC lies in the scope of testing. COSC focuses on the movement alone, while METAS evaluates the entire watch as a fully assembled unit. This means METAS tests how the watch performs under real-world conditions, including exposure to magnetism, temperature fluctuations, and water.

To qualify for METAS certification, a watch must first be Swiss-made and already COSC-certified. While COSC primarily examines timekeeping accuracy, METAS also assesses magnetic resistance, water resistance, and power reserve.

METAS Testing Methods

METAS certification involves a rigorous, 10-day testing process that includes eight separate evaluations to ensure the watch meets exacting standards. Here’s a breakdown of the testing:

- Precision Testing: Accuracy is measured at two temperatures – 91°F for 14 hours and 73°F for 10 hours – across six positions and at both full power (100%) and partial power (33%) reserves.

- Magnetic Resistance: The watch is exposed to a magnetic field of 15,000 gauss while its accuracy is monitored. This ensures the movement continues to function flawlessly in high-magnetic environments.

- Water Resistance: Watches are tested under pressures ranging from 3 bar (98 ft) to 150 bar (4,921 ft), depending on their specifications. Afterward, a condensation test is performed by applying a drop of cold water to the crystal after the watch has been heated to 104°F–113°F. Any sign of condensation means the watch fails.

METAS also sets a stricter daily accuracy standard of 0/+5 seconds per day, compared to COSC’s -4/+6 seconds.

| METAS vs. COSC Comparison | COSC | METAS |

|---|---|---|

| Component Tested | Uncased movement | Fully assembled watch |

| Accuracy Standard | -4/+6 sec/day | 0/+5 sec/day |

| Magnetic Resistance | Not tested | 15,000 gauss |

| Water Resistance | Not tested | Yes |

| Power Reserve | Not tested | Yes |

This table highlights how METAS goes beyond COSC by addressing a broader range of performance factors.

Benefits of METAS Certification

For watch enthusiasts, METAS certification is a mark of exceptional reliability. It ensures that a timepiece maintains precision even when exposed to magnetic fields as strong as 15,000 gauss. The transparent certification process, which allows buyers to verify test results online, adds an extra layer of confidence.

METAS certification has also raised the bar across the industry, encouraging brands to meet higher standards of durability and performance. For owners of certified watches, this means both timekeeping and chronograph functions are built to handle the challenges of everyday life.

Considering that only about 6% of all Swiss mechanical watches achieve COSC certification, and an even smaller percentage pass the additional METAS tests, these watches represent the pinnacle of Swiss craftsmanship and performance.

sbb-itb-fcc00bb

The Geneva Seal and Other Swiss Hallmarks

Swiss certification goes beyond just testing movement performance – it also celebrates the artistry and craftsmanship that make traditional watchmaking so special. While standards like COSC and METAS focus on precision, hallmarks such as the Geneva Seal highlight the complete mastery of artisanal watchmaking.

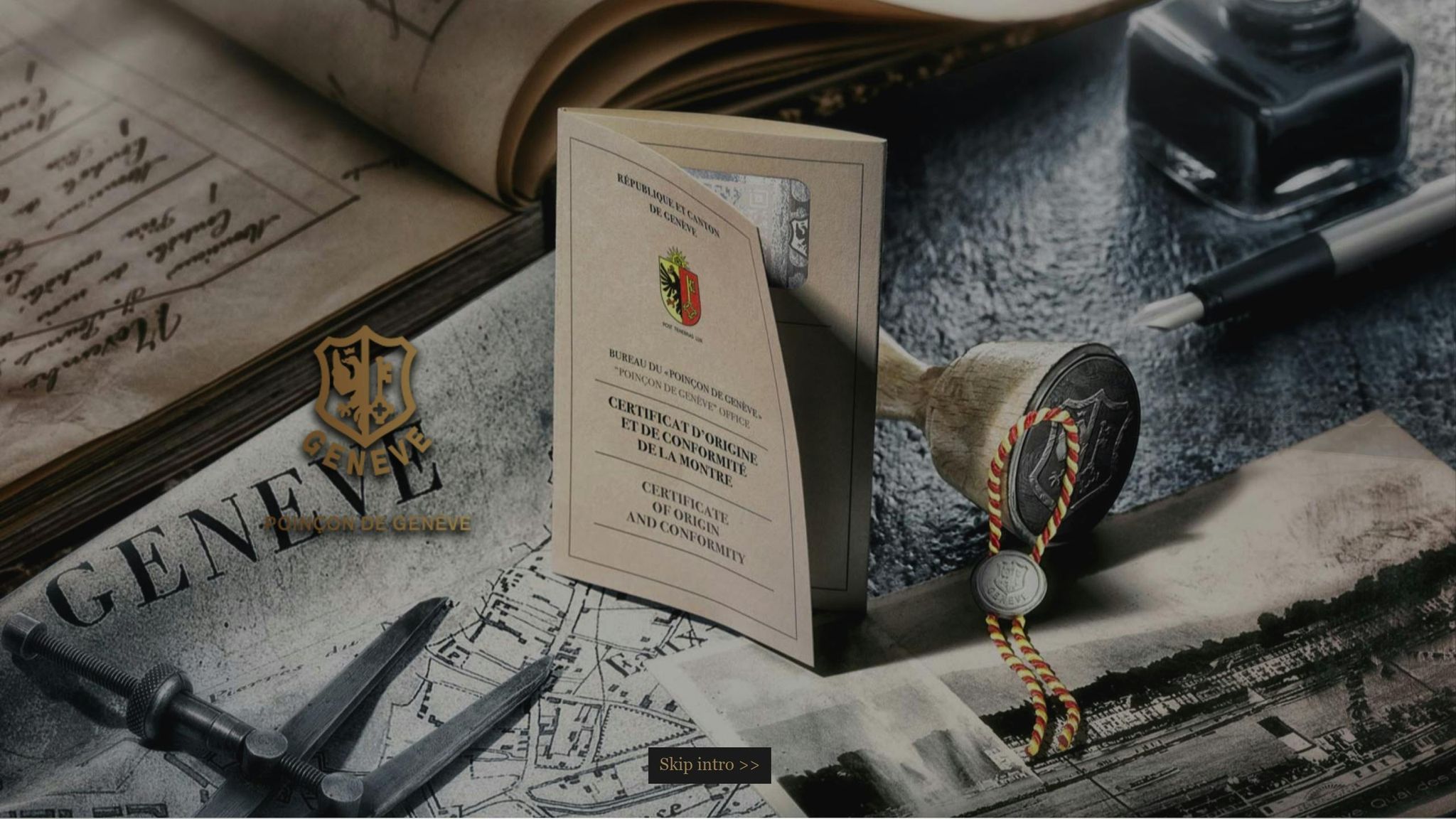

Understanding the Geneva Seal

The Geneva Seal, or Poinçon de Genève, is one of the oldest and most respected quality standards in the watchmaking world, dating back to 1886. It is exclusively awarded to watches produced in the Canton of Geneva that adhere to its rigorous standards.

Initially, the Geneva Seal primarily recognized exceptional movement finishing, emphasizing decorative artistry. Over time, it expanded to include reliability tests while still prioritizing traditional craftsmanship. Interestingly, in the mid-1990s, Patek Philippe accounted for 95.7% of all Geneva Seals awarded, showcasing their dominance in this category.

Geneva Seal Testing and Requirements

To earn the Geneva Seal, a watch must meet strict criteria for both aesthetics and performance. Specifically, it requires a precision of –1/+1 minute per week. The evaluation process scrutinizes everything from movement finishing to case construction and overall assembly quality, with a strong focus on traditional hand-finishing techniques.

While the Geneva Seal is iconic, other certifications also recognize excellence in Swiss watchmaking.

Other Swiss Watch Hallmarks

One standout certification is the Patek Philippe Seal, introduced in 2009. This hallmark is considered one of the most demanding in the industry. Unlike the Geneva Seal, it evaluates the entire watch – movement, case, dials, hands, straps, buckles, and more. It also enforces stricter performance standards, requiring accuracy within –3/+2 seconds per day for calibers measuring 20 mm or larger. Beyond precision, the Patek Philippe Seal includes a lifetime service guarantee, reflecting the brand’s commitment to quality.

Another noteworthy certification is offered by the Fleurier Quality Foundation (FQF). Established in 2001, the FQF takes a comprehensive approach, assessing technical design, high-quality finishing, and precision. Its rigorous testing has inspired the creation of similar high standards within the industry.

| Certification | Authority | Precision Requirement | Focus Area |

|---|---|---|---|

| Geneva Seal | Canton of Geneva | –1/+1 minute per week | Craftsmanship and Genevan traditions |

| Patek Philippe Seal | Patek Philippe | –3/+2 seconds per day | Complete watch performance |

| Fleurier Quality Foundation | FQF | Varies by test | Technical conception and finishing |

For collectors who value the authenticity of precious metals, Swiss hallmarks have been in use since 1880. These include symbols like the Helvetia head for 18k gold and the squirrel for 14k gold, as well as the grouse for 800 silver and the bear for 875 silver. Additionally, the Poinçons de Maître, introduced in the 1920s, identify the case maker, offering added traceability and assurance.

These certifications and hallmarks represent more than just precision – they embody the artistry and meticulous craftsmanship that define the timeless appeal of Swiss watchmaking.

Chronograph Testing in Swiss Standards

When it comes to Swiss certifications like COSC and METAS, precision is the name of the game. These certifications ensure the accuracy of a watch’s movement, but chronographs require additional tests to confirm their reliability in everyday scenarios. Here’s a closer look at how these rigorous standards address the unique challenges of chronograph mechanisms.

Tests for Chronograph Movements

Chronograph movements undergo the same strict protocols as standard Swiss watches, but with extra attention to timing accuracy. For COSC certification, chronographs must maintain a daily accuracy of –4 to +6 seconds over a 15-day testing period. These tests include evaluations of mean rate, positional shifts, and performance under temperature ranges from 46°F (8°C) to 100°F (38°C). METAS certification takes things further, requiring resistance to magnetic fields up to 15,000 gauss. Some brands, such as Rolex, impose even tighter standards, like the –2 to +2 seconds per day required for their Superlative Chronometer certification.

While precision is critical, the ability to maintain performance over time is just as important.

Durability and Practical Testing

Chronograph mechanisms have to prove they can handle the wear and tear of daily use. Components like pushers, levers, and gear trains face repeated stress, so durability testing is essential. For example, Jaeger-LeCoultre’s "1000 hours" test subjects each watch to 42 days of evaluation, simulating real-world conditions across six positions and through cyclotesting. Other tests assess power reserve, water resistance, and temperature performance up to 104°F (40°C). Pushers are also tested to ensure they remain reliable after extensive use.

| Testing Focus | Standard Requirement | Enhanced Standards |

|---|---|---|

| Daily Accuracy | –4 to +6 seconds (COSC) | –2 to +2 seconds (Rolex) |

| Magnetic Resistance | 15,000 gauss (METAS) | Varies by manufacturer |

| Testing Duration | 15 days (COSC) | 42 days (Jaeger-LeCoultre) |

Swiss chronograph testing is as thorough as it gets, ensuring these intricate timepieces deliver both precision and durability. COSC Director Andreas Wyss highlights the importance of adapting to industry advancements, saying:

"The watch industry has had big evolutions. We need to follow them, and we need to evolve."

For watch enthusiasts, understanding these testing standards not only reveals the engineering prowess behind Swiss chronographs but also offers a glimpse into the constant innovation driving the world of horology.

Conclusion

Swiss chronograph testing standards have long been the gold standard for precision and reliability in luxury timepieces. The rigorous protocols set by COSC, METAS, and the Geneva Seal ensure that certified chronographs consistently deliver the exceptional performance expected of high-end watches.

Why Swiss Standards Matter

Swiss certifications go beyond simply ensuring timekeeping accuracy – they serve as independent guarantees of quality, earning global recognition and trust. COSC’s guiding principle captures this commitment perfectly:

"Quality, rigor and impartiality are the very foundations of the COSC label."

The rarity of these certifications further enhances their prestige. Only about 6% of all Swiss watches exported are COSC-certified, making certified chronographs rare feats of mechanical craftsmanship. Meeting the stringent criteria of COSC and METAS is a testament to a watch’s engineering excellence.

These standards also push the industry forward. COSC Director Andreas Wyss highlights this evolving commitment:

"We have to promote not only the accuracy but the excellence of Swiss watches. Until now, we were not open to the public. We will change that."

What Collectors Should Keep in Mind

For collectors, certifications are more than technical benchmarks – they have a direct impact on a watch’s market value and reliability. However, as watch expert Kas Klerx points out:

"Certification is a guarantee at the point of testing. That’s all."

Over time, factors like wear, exposure to magnetism, or missed servicing can affect a watch’s performance, even if it was initially certified. This makes regular maintenance essential for preserving its accuracy.

When buying certified chronographs, especially pre-owned models, verifying authenticity through proper documentation and movement references is crucial. Tools like a timegrapher can help assess whether a watch still meets COSC standards, offering a practical snapshot of its current condition.

Certified chronographs also tend to hold their value better than non-certified models. These certifications not only enhance a watch’s resale potential but also tell a story of technical precision and reliability. For collectors focused on precision and legacy, certified chronographs provide a tangible assurance of quality.

Proper care and maintenance are equally important. Resources like Chronoexpert offer guidance on protecting high-end timepieces, from maintenance tips to insurance options, ensuring that certified chronographs maintain their performance and value over time.

Ultimately, Swiss chronograph testing standards are about more than just technical specifications. They embody centuries of horological tradition and mechanical mastery, ensuring that every certified timepiece lives up to the reputation of Swiss watchmaking excellence.

FAQs

What sets COSC, METAS, and the Geneva Seal certifications apart in Swiss chronograph testing?

Swiss chronograph certifications – COSC, METAS, and the Geneva Seal – each evaluate different aspects of a watch’s quality and performance, offering unique benchmarks for excellence.

COSC (Contrôle Officiel Suisse des Chronomètres) focuses on precision. It tests a watch’s movement over 15 days, assessing its ability to maintain accuracy between -4 and +6 seconds per day. These tests are conducted in five positions and across three temperature ranges, ensuring the movement performs reliably under varying conditions.

METAS (Swiss Federal Institute of Metrology) takes precision testing a step further. Building on COSC standards, it evaluates magnetic resistance up to 15,000 gauss and requires timekeeping accuracy between 0 and +5 seconds per day. This certification emphasizes both precision and the ability to endure challenging environments, simulating everyday wear.

The Geneva Seal, dating back to 1886, represents a different kind of excellence. While it includes quality checks, its primary focus is on craftsmanship and the aesthetic beauty of the watch. This certification is a mark of superior artistry, highlighting exceptional finishing and design rather than strict performance metrics.

In essence, COSC and METAS center on precision and durability, with METAS setting tougher standards, while the Geneva Seal celebrates the artistry and elegance that elevate a timepiece to a work of art.

Why is the COSC certification highly regarded even though it only tests the watch movement?

The COSC (Contrôle Officiel Suisse des Chronomètres) certification is a hallmark of precision and dependability in watchmaking. Over a rigorous 15-day testing period, a watch’s movement undergoes evaluation in five positions and at three different temperatures. This ensures it meets the stringent Swiss standards for timekeeping accuracy.

Though the certification applies specifically to the movement rather than the fully assembled watch, it represents a commitment to excellence. For many, COSC certification stands as a testament to the meticulous craftsmanship and high standards that define the luxury watch industry.

How do Swiss chronograph testing standards influence the value and reliability of luxury watches?

Swiss chronograph testing standards, such as COSC and METAS certifications, are pivotal in ensuring the precision and craftsmanship of luxury watches. These certifications involve rigorous testing to verify that a timepiece meets strict performance benchmarks. For example, a COSC-certified watch guarantees an accuracy range of -4 to +6 seconds per day, showcasing its high level of precision.

Watches that pass these tests are often regarded as more reliable and prestigious, making them especially appealing to collectors and enthusiasts. This reputation not only strengthens consumer trust but also enhances the watch’s allure and resale value in the luxury market. By adhering to these demanding standards, Swiss watches continue to uphold their reputation as the ultimate symbol of quality and performance in the industry.